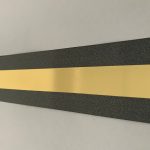

Edge bands, It is one of the products that are frequently needed and used especially in the furniture sector. These products can generally be defined as thin strips and bands made to cover the areas of furniture. Since edge bands are preferred in the furniture industry, their colors and models can often be different from each other.

Thanks to these bands, which can be defined as thin and wooden bands during their production, the furniture is completed visually. Therefore, it is almost mandatory to use wooden bands for furniture or PVC. In addition to being compulsory, these tapes must be used for a beautiful image.

Edge Band Models

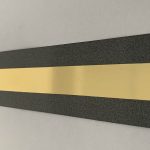

Edgeband models It may vary depending on the furniture and situation to be used. In this regard, there are many different edgebanding models such as PVC edgebanding, 3D edgebanding, bottom edgebanding. Among these models, PVC edge bands are among the thinly used and preferred models. These models are models that make a difference in appearance and are different from each other. With these models, which are slightly different from each other in terms of both appearance and handsome construction, a different touch is provided to the furniture.

Since edge bands are very effective in aesthetic appearance, it is generally necessary to produce them carefully. In this way, the best edgebanding is revealed.

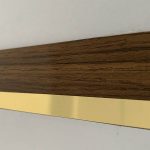

Chipboard Edge band

Chipboard edge band In terms of production and texture, it refers to the edge bands made of chipboard material. The furniture is sometimes used in the edge banding in order to adapt to the edge banding of the work done with chipboard. In this way, the furniture is bubanded in the best way. is completed with.

Colors may also be different from each other in the use of chipboard edgebanding. In this color production, as in the texture, the colors suitable for the furniture are selected and a production is made accordingly. .

Furniture Edge Banding

Furniture edge band refers to adhesive wood tapes used to complete the edges of furniture. Its texture and color can be different from each other at any time edge bands It is considered a complementary element to the furniture. There are many kinds of production in edge bands, which have both different models and different colors.

Edge bands are among the bands used first in the furniture industry today. Therefore, especially Furniture edge bands are the bands that are frequently preferred and needed to be used. Thus, a complementary element is produced in the furniture industry.

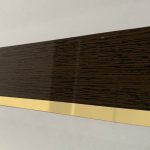

Wooden Edge Band

Wood edge band , edge bands It refers to the edge bands produced from wood as texture in its production. Since these tapes are used in the furniture industry, the time may be different for schools. In addition, since it is a complementary element to the furniture, it is produced in wooden texture to complete the mobile bow in a beautiful way.

In addition to producing wooden texture, wooden edge bands are produced in different colors in terms of completing the furniture in terms of color. These tapes, which are produced in high quality, are tapes that both complement the furniture and provide a more aesthetic appearance in appearance.

Edge Band Prices

Edge band prices , This is an area of particular interest. Since the models and colors are different from each other in the prices of the edge bands, the prices also usually differ. In addition, prices will also differ depending on what size and what size these bands are.

How is Edge Banding Made?

How to do edge banding the subject is one of the most frequently asked questions. Since these tapes are generally sticky, they are very easy and practical to use. Depending on its shape and model, it is possible to use the furniture as a complementary element by removing it from the adhesives of the edge bands. By purchasing these edge bands, which are both easy to use and stylish in appearance, it is possible to completely complete the furniture and make it more beautiful. Thanks to the edge banding service to be obtained from a correct and high-quality company, the furniture industry will have a fully aesthetic appearance.

Why are Edgebands Used?

Edge bands It can be considered as a complement to furniture in general. For this reason, thanks to these tapes, which are frequently used in the furniture industry, the furniture gains a much different appearance. Even though furniture usually tries to produce light during production, it becomes even more elegant thanks to these edge bands. Thanks to the correct use and the edge bands produced in a quality texture, a practical service is always provided.

Since the edge bands are in different textures and colors, they always make the environment more beautiful. It is also very easy to use and adhesive in a way that anyone can use.

Edge bands are produced in a way that appeals to all tastes thanks to their different colors and models. Today, the furniture industry is always one of the most sought-after industries. But when these sectors are producing, fine details are always the most striking situations. Therefore, it is absolutely necessary to use edge bands, which are complementary elements to these fine details.

When choosing, it is important to choose an edge band that is suitable for the texture and color used in furniture production. Thanks to the right choice and the edge band produced with a quality material, the furniture becomes much different. With a nice touch of edgebanding, furniture always becomes more stylish in homes and environments. That’s why too edge bandsthey are very functional products.

Frequently Asked Questions

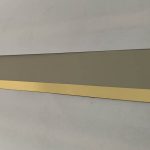

What is PVC Edge Banding?

PVC edge banding is a process used in furniture and interior decoration. In this process, tapes made of PVC (Polyvinyl Chloride) material are glued to the edges of the furniture panels. PVC edge banding is used to increase the aesthetic appearance of furniture, protect its edges and increase its durability.

How many mm of PVC edge banding?

PVC edgebandings are available in different thicknesses and widths for furniture and interior decoration applications.

What does edgebanding do?

Edge banding, It is an important material used in furniture production and interior design for aesthetic and functional purposes. These tapes are used to cover the edges of furniture panels, especially those made from materials such as MDF, chipboard or plywood. Edge banding complements the overall look of the furniture, offering a more professional and finished aesthetic. Available in different colors, patterns and textures, edgebands provide a harmonious integrity with the design of the furniture. Available in a wide range of wood patterns, glossy or matt finishes, these bands offer flexibility and variety in the design of furniture. In this way, it can be used in the production of furniture in both classic and modern styles, enhancing the visual appeal of furniture and meeting customers’ expectations.

Where is PVC tape used?

PVC tape is a versatile material that is widely used in a variety of fields and applications. Here are the main uses of PVC tapes:

-

Furniture Production:

- Edge Coating: Provides an aesthetic appearance by covering the edges of furniture panels and protects the edges.

- Cabinet and Shelf Systems: It is used in kitchen cabinets, bathroom cabinets, wardrobes and other shelf systems to protect the edges and give an aesthetic appearance.

-

Interior Design:

- Door and Window Edges: By covering door and window edges, it provides both a decorative appearance and protects these areas against impacts.

- Wall Panels: Used to seal the edges of wall cladding panels in a neat and finished manner.

-

Office Furniture:

- Desk and Work Surfaces: Used to cover the edges of office desks, work tables and other work surfaces.

- Storage Units: Provides edge protection for filing cabinets, shelving systems and other storage units.

-

Shop and Exhibition Stands:

- Showcase and Display Units: Provides an aesthetic and protective coating on the edges of shop windows and exhibition stands.

- Aisles Protects the edges of the product display aisles and offers a decorative appearance.

-

Home Decoration:

- Furniture Repair: Used to renew and repair the edges of worn or damaged furniture.

- DIY Projects: Used as a decorative and protective coating in do-it-yourself (DIY) projects.

-

Industrial and Commercial Areas:

- Warehouse Shelf Systems: Provides edge protection in shelf systems in warehouse and logistics areas.

- Production Facilities: Used to protect the edges of various production equipment and machinery.

-

Education and Health Institutions:

- School Furniture: Protects the edges of school desks, lab tables and other educational equipment.

- Hospital Furniture: Used to cover the edges of hospital beds, cabinets and other healthcare equipment.

PVC tape is an important material used in a wide range of applications thanks to its durability, flexibility and various aesthetic options. Thanks to these features, it is frequently preferred in both home and commercial areas.

How to remove furniture edgebanding?

Removing furniture edgebanding is a process that requires care and attention. One wrong step can damage the furniture. Here’s how to remove furniture edgebanding step by step:

Required Ingredients:

- Heat gun or hair dryer

- Thin spatula or knife

- A clean cloth

- Sandpaper (optional)

- Adhesive remover or acetone (as needed)

Steps

-

Preparation:

- Move the furniture to a well-lit area where you can work comfortably.

- Clean the surface of the furniture and check the edges of the tape.

-

Heating

- Heat the edging tape using a heat gun or hair dryer. The heat softens the adhesive and makes the tape easier to remove.

- Apply the heat directly onto the tape, but be careful not to damage the surface of the furniture.

-

Disassembly:

- Lift one corner or end of the tape with a thin spatula or knife.

- Gently and carefully pull the tape off. If the tape is difficult to remove, apply heat again and soften the adhesive.

-

Removing Adhesive Residue:

- After completely removing the tape, remove any adhesive residue left on the surface with a clean cloth and adhesive cleaner or acetone.

- If you use acetone, make sure it does not damage the furniture surface. You can start by experimenting in a small area.

-

Surface Smoothing (Optional):

- If roughness or adhesive residue remains on the surface, smooth the surface with fine sandpaper.

- Be gentle when sanding and be careful not to damage the surface of the furniture.

Tips

- Take your time when removing the edge banding. Working slowly and carefully reduces the risk of damaging the furniture.

- Make sure to apply enough heat before removing the tape. Insufficiently heated adhesive can cause the tape to come off with difficulty and damage the furniture.

- If you have a lot of furniture edgebanding to do, a heat gun can make your job easier and get faster results.

By following these steps, you can successfully and safely remove furniture edgebanding.